A Passion for Turning Quality Parts

Certainly, were always striving for Quality Machined Parts Turning. Hence, Sentinel is a leading force in the UK’s Plastic CNC Machining and Fabrication industry. Thus, through the highest industry and Quality standards with BSI. Also, the way in which we strive for customer satisfaction through excellence. Moreover, consistently delivering outstanding Plastic Parts and Components. Hence, ensuring our customers have a trustworthy, predictable, world class supply chain. Subsequently, helping to enhance their own competitive advantage.

Importantly, Sentinel also excel in the eyes of our customers. Always seeking to understand their requirements and providing innovative, flexible and on-time solutions. Thus, our reputation, Experience, knowledge in Plastic Materials and Machining techniques guarantee consistently first-class Components. Certainly, A Plastics Company with a Passion for Component Turning. Above all, we strive for continuous Quality improvements. Thus, using innovation with every product and process. Lastly, A commitment we make to our customers and is at the heart of everything we do.

Component Quality Control in Production

Significantly, for many years, the company has been working with the B.S.I. maintaining our I.S.O. 9001 Quality standard. This, combined with a long proven track record, shows our commitment to Quality.

Most noteworthy, Quality and Production control must go hand in hand. Thus, Sentinel has a database which helps tightly control the day to day running of production and Quality. Importantly, with strategically placed process recording stations in position around the shop floor. Also, meaning customers can be updated instantly on the progress of their orders.

Sentinel Turning Component Overview

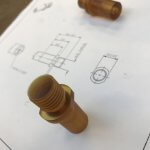

Certainly, Sentinel is an Engineering Plastic Machining Turning Company, specialising, not only in Turned Plastic Components. But, also, Plastic Machining & Plastic Fabrication of all types of Machined Plastic Parts to customer specifications.

Most importantly, we consider ourselves ‘The One Stop Shop’ for Plastic Engineering Components and Fabrications, one of, if not the top Plastics Companies in the UK. If you require an excellent Turning Service, provided by a team of Experienced professionals dedicated to excellence and high production Quality in a variety of Materials. Certainly, Sentinel Plastic Services has the ability and Experience to be your perfect Manufacturing supplier to deliver all your Machining requirements on time and on budget.

At Sentinel your Parts can be Turning or Milled as well as Routed and Fabricated. Welding, Polishing and Assembly of Parts are just some of the other Services available. Whether you require Precision Parts, Prototypes, Production Batches or just some help and advice. Sentinel staff are more than willing to help.

Ideally Located to Supply all Plastic CNC Machining Requirements

Significantly, Sentinel is strategically positioned in the heart of the West Midlands. A valuable position for a business that supplies Companies all over the UK and Europe. Markedly, Sentinel has clients in China and the USA as well as in the local vicinity. Having an already large client base, among whom it can boast many long-term blue-chip clienteles. Furthermore, the Company is currently attracting large amounts of extra business. Mainly through reputation, but, also due to a very active and successful marketing team.

Plastic Turning Components Capacity

Significantly, Sentinel have 15 No CNC Machines, which includes 2 Mazak VCN 530C with 5 No XYZ 1020 VMC. Also 3 Bridgeport’s VMC plus 2 ProTurn Lathes and a 2 Mazak Mill/Turn. Notably, These are just a few of the machines that are available to produce Quality plastic CNC components.

Contact us for your Plastic Turning Components and More

Finally, peruse the website, drop your enquiry on an email or please do give us a call.