Polycarbonate Machining

March 15, 2017

Polycarbonate Machining

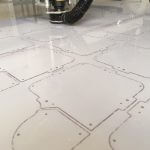

Firstly, without doubt, Sentinel leads the field when it comes to Polycarbonate Machining Experience and ability. Hence, at any one time, all Five, of our 3Mx2M CNC Routers. can be Machining Polycarbonate Sheet ( Makrolon – Lexan ).

SEND IN YOUR ENQUIRY

CNC Routing Polycarbonate -Lexan -Makrolon

Polycarbonate Machining -Lexan -Makrolon

Ultimately, with its high transparency and smooth surface, Clear Polycarbonate Machining is an attractive Material for a wide range of applications. Thus, offering extreme impact resistance, even at temperatures down to -100°C.importantly. Which, unlike Acrylic, which requires heat to form, Polycarbonate sheets can be CNC Routed and cold bent.

So notably, as a Company, Sentinel Plastics has become synonymous with Polycarbonate Machining and Fabrication. Also, importantly, Polycarbonate is the most popular choice of Plastic. Certainly, when it comes to a requirement of strength and ultimately safety. Furthermore, while in its Sheet form, it is extremely impact resistant. Further, interior applications, up to 6 mm thickness Polycarbonate has a B1 fire protection for classification.

Polycarbonate Applications:

Firstly, many Parts Manufactured by Polycarbonate Machining, are guards, screens and covers. Also. Glazing for commercial business and factories. Plus, Safety doors. Certainly, high usage for sneeze guards, make it a popular Material. Further, widely used for Industrial vehicles and Lamp covers. Also, where a high level of heat is generated, being highly fire-resistant, versions exist for the use in Switch cubicles, electrical equipment.

Furthermore, other uses for Polycarbonate are Trade fair structures and Public buildings. Certainly, within the Industry, the clear Plastic of choice is Polycarbonate. Hence, its popularity and wide use as safety guards.

In addition, UV coating can be applied to the surface of the smooth or textured Polycarbonate sheets. Plus, solid sheets retain their shine with no yellowing, nor change of colour. Also, the positive effect in applying a protective coating, is that you are increasing the resistance to long-term weathering. Thus, provides a long Service life.

Polycarbonate Machining – Parts Available in:

Moreover, Polycarbonate, available in Transparent clear and white translucent. Also, available in bronze, grey, green, blue.

Further,available grades: Polycarbonate Machining

1: Polycarbonate Sheet / FG food grade

2: Solid Polycarbonate Sheet / FR flame retardant

3: Polycarbonate Sheet / NR non reflective

4: Outstanding through reinforced UV protection.

Noteworthy, Some information gathered from Bayer. Read more HERE

Contact now

Contact now

TALK TO OUR EXPERTS About Sheet Polycarbonate Machining

Further, For More in depth information, Follow the Quick Links below.

Furthermore, Plastic Materials Machined

Sentinel Plastics Business Google – LinkedIn Plastic Machining Company – Sentinel Plastic News on Twitter