Ultem Machined @ Sentinel Plastics Ltd

February 26, 2019

Ultem Machining – Ultem ® / PEI (Polyetherimide)

Firstly, for many years, ever since its inception in 1989, the name Sentinel has always been synonymous for high Quality Ultem Machining. The material Ultem, is a high-strength amorphous polymer with excellent heat and flame resistance, (carrying a flammability rating of 94-V-0) with little smoke output. Furthermore, it performs continuously to 340° F, making it superior to commodity Plastics such as Nylon and Delrin®. Also, Ultem ® is an ideal solution for applications that require high strength and the ability to withstand high temperatures. Finally, the product also suits applications that require consistent dielectric properties over a wide range of frequencies.

Furthermore, always providing exceptional CNC Machined Plastic Parts through 27 years of Experience in Plastic production. Most notably, having the ability to accomplish tight tolerances. Further, having a great depth of knowledge when, CNC Milling and Turning the huge variety of Plastic Materials available today. And, because Sentinel works solely with Plastic, we have a focus that gives us an edge over many of our competitors in the industry.

Where Is Ultem Used

Notably, being hydrolysis resistant and highly resistant to acidic solutions, and can tolerate repeated autoclaving cycles, such as with repeated steam sterilization of reusable medical devices. Thus, Ultem ® is widely used in electronics because of its good arc resistance and dielectric constant. Therefore, other typical applications include analytical instrumentation and structural Components that require high strength and rigidity at elevated temperatures.

Key Properties – Ultem

LONG-TERM HEAT RESISTANCE – Ultem

Importantly, Ultem has excellent stability of physical and mechanical properties, So, at elevated temperatures thanks to high Glass transition temperature of 217 °C. Also, available with relative thermal indices (RTI) up to 180 °C

STRENGTH AND STIFFNESS

Also, Ultem has outstanding strength and amorphous thermoplastic among the available alternatives. furthermore, predictable stiffness and strength up to 200 °C. Furthermore, Transparent grades are equal in strength to other thermoplastics with opacifying fillers.

DIMENSIONAL STABILITY

Certainly, one of the most dimensionally stable thermoplastics available, offering predictability over a wide temperature range. While also, filled grades offer exceptionally high-tolerance dimensional capabilities.

ENVIRONMENTAL STRESS & CRACKING RESISTANCE

Moreover, unlike most other amorphous thermoplastics, Ultem Machining resins retain strength and resist stress cracking when exposed to automotive and aircraft fluids, aliphatic hydrocarbons, alcohols, acids, and weak aqueous solutions.

FLAMMABILITY, SMOKE GENERATION AND TOXICITY

Also, Inherent flame resistance without additives in most grades, I.E. exceptionally difficult to ignite. Plus, a limiting oxygen index (LOI) of 47%, meeting UL94 V0 specifications in sections as thin as 0.41 mm. Furthermore, generating extremely low smoke per the NBS smoke evolution test, with products of combustion no more toxic than those of wood.

PROCESSABILITY

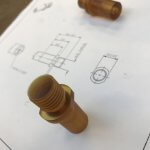

Above all, Ultem can be CNC Machined, Turned & Milled, to a high-Quality standard.

Importantly, Sentinel has eight Plastic CNC Milling Machines. All of which, can produce almost any cut shape from the extensive range of Industrial Plastics available in today’s market, Including Ultem Plastic

Having cutting tables, which can take large Sheet sizes up to a maximum of 3000mm x 2000mm and Materials ranging from 1mm up to 50mm in thickness. Our top brand name Machines can achieve high standard finishes and sizes every time.

Importantly, Sentinel has four Plastic CNC Turning Lathes All can produce, almost any Turned or Milled shape, from the extensive range of Industrial Engineering Plastics available in today’s market. Including Ultem Machining.

Our top brand name Machines can achieve high standard finishes and sizes every time. Ultimately, our Experienced at Sentinel has many years’ Experience and knowledge in Machine exceptional Quality Plastic Parts. for various industries including medical, subsea and power control.

Standard Shapes and Forms

Sheet: .040” – 4” thick

Rod: .187” – 8” diameter

The range of sizes and shapes are grade specific.

Grades

Ultem ® 1000

Further, Ultem ® 1000 is the standard, unfilled grade of Ultem ®. Also, resistant to UV and gamma radiation. Furthermore, performs especially well in hot air and water environments. Hence, retains 85% of its tensile strength after 10,000 hours of immersion in boiling water and 100% of its tensile strength after 2,000 cycles in a steam autoclave at 270°. Further, Ultem® 1000 is FDA and USP Class VI compliant and USDA and NSF approved. The standard colour is amber.

Also, Ultem® 2300 is a 30% Glass-reinforced grade of Ultem ®. The addition of Glass fibre provides greater tensile strength and rigidity while at the same time improving the product’s dimensional stability. Lastly, the standard colours are tan and green.

In Conclusion:

Finally, Sentinel Plastics Ltd is versatile, Experienced, flexible, always aiming to be as helpful as possible. Hence, if its Plastic cutting, that does not constitute Molding or Extruding then there is a good chance we can help!

More info: https://www.sabic.com/en/products/specialties/ultem-resins/ultem-resin

Information taken from www.sabic.com & www.aetnaplastics.com

Further, For More in depth information, Follow the Quick Links below.

Further, Plastic Materials Machined

Sentinel Plastics Business Google – LinkedIn Plastic Machining Company – Sentinel Plastic News on Twitter